First, identify the manufacturing expenses in your business for a given period. Effective management of overhead can impact a company’s profitability, as fewer overhead costs generally lead to higher profitability. A low manufacturing overhead rate signifies efficient and effective resource utilization within your business. However, a higher rate may suggest your production process is experiencing delays or inefficiencies. Businesses should regularly calculate their overhead percentage to monitor financial health and operational efficiency. A consistent review allows for the identification of any significant shifts in overhead costs, which can impact overall business performance.

Pricing Strategy

To calculate manufacturing overhead, you need to add all the indirect factory-related expenses incurred in manufacturing a product. This includes the costs of indirect materials, indirect labor, machine repairs, depreciation, factory supplies, insurance, electricity and more. Understanding your overhead rate can also highlight which of your products or services are profitable and which aren’t. While a product may appear profitable based only on its direct costs, assigning an overhead cost to each unit could reveal a significantly smaller profit margin.

The Best Manufacturing Quoting and Estimating Software

Encouraging a culture of how to determine overhead rate cost consciousness among employees can also contribute to long-term reductions in overhead percentage. This means for every hour of direct labor, you’re incurring $20 in overhead costs. Calculating it accurately ensures better financial planning, pricing, and cost control.

- This can be a measure of those costs that are directly allocable to particular activities or product lines, the company’s total sales, or some other measure.

- Understanding your overhead expense rate is key to gaining an accurate picture of your business finances.

- While you pay a standard fee for the monthly plan, this could increase when the employee travels for work and uses roaming or exceeds their data allowance.

- Analyzing competitors’ overhead rates is a valuable exercise in understanding your company’s position within its industry.

- Overhead rate is a ratio that measures overhead or indirect costs against direct costs, machine hours, or labor hours.

- Overhead, on the other hand, is the money spent on costs that don’t translate directly into production and revenue for the business, like insurance, rent, software, etc.

How do you calculate the overhead rate per employee?

- That means you put your labor force into optimum utilization at minimum overhead costs.

- Not knowing your overhead costs could result in you pricing your products too low and not making a profit.

- The first thing you have to do is identify the manufacturing overhead costs.

- Learn more about what’s included in overhead costs, good overhead percentages, and more with frequently asked questions about overhead costs.

- If you choose machine hours but your overhead costs are driven more by labor time, your product costs will be distorted.

Track how your https://www.audiotech.ro/2024/11/18/free-bookkeeping-course-learn-the-basics-of/ overhead rate changes at different volume levels to optimize your fulfillment routing decisions. General business expenses like corporate office rent or sales team salaries don’t belong in manufacturing overhead. Their overhead includes large facility costs, extensive testing equipment, and significant utility expenses. Many use a hybrid allocation base or separate overhead pools for different production stages.

Overhead Rate Formula: A Comprehensive Guide

Tracking these costs and sticking to a proper budget can help you to determine just how efficiently your business is performing and help you reduce overhead costs in the future. Organizing your overhead expenses into categories makes it easier to keep track of expenses and assess which costs Outsource Invoicing are most beneficial to your business. Semi-variable overhead expenses are costs that have a fixed baseline expense but may also fluctuate in relation to business activity. For example, utility costs typically include a base monthly delivery charge but also increase depending on how much heat, water, or power you use. Overhead costs include all the expenses that keep your business functional but aren’t tied directly to production or sales.

- For example, if your forecast assumes 10% headcount growth and you know your average overhead per employee, you can model future costs accordingly.

- Understanding how to calculate manufacturing overhead correctly is crucial for financial stability and long-term success.

- Investing time into overhead analysis and accurate calculation of rates leads to better accounting and superior business management.

- Unlike direct materials and direct labor that go straight into making your products, overhead covers everything else required to keep your manufacturing operations running.

- Indirect expenses refer broadly to all other costs not directly involved in production.

- Then, multiply the overhead cost per labor hour by the number of labor hours required to produce one unit to get the overhead cost per unit.

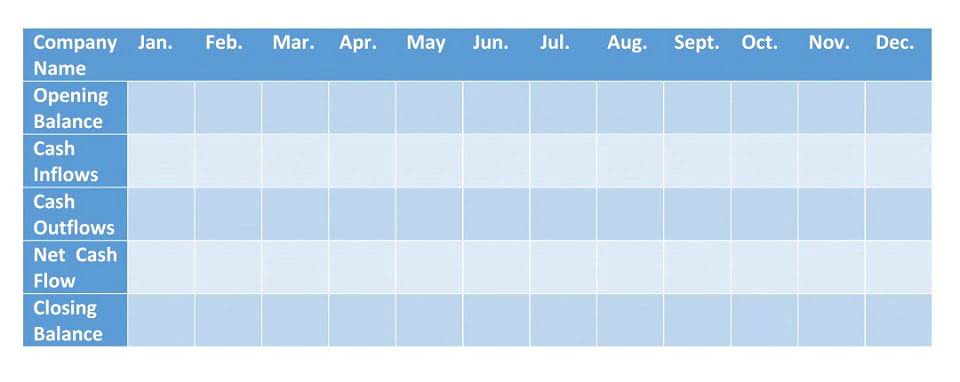

Because even if you pay certain expenses on an annual basis, you should set aside money every month to cover the cost. Following the calculation of the Total Recoverable Salary for everyone at your firm AND the Total Overhead, the next step is to calculate your Overhead Percentage figure. To do this, divide your Total Overhead figure by the Total Recoverable Salary figure. Flxpoint brings all your inventory, orders, and fulfillment channels together in one platform. Schedule a demo today to see how we can help streamline your operations and improve profitability. Look for the largest overhead categories and brainstorm ways to optimize them without compromising quality.

How to calculate overhead costs with an example

When assessing the overall costs of your business, it’s important to consider both overhead and direct costs. Direct costs are directly connected to the output of a product or service, such as labor and materials. However, if you’re looking at overall costs and want a more informed way to price your products or services, you may want to use sales or labor hours. Once you’ve calculated your overhead costs for a specified time frame, you’re ready to complete the overhead rate calculation. To calculate your overhead percentage, you’ll use a simple formula that compares your total overhead expenses to your total revenue.

Indirect Cost vs. Direct Cost: What is the Difference?

Overhead costs are the ongoing business expenses that cannot be directly attributed to creating specific products or services. Unlike direct costs that fluctuate with production volume, overhead expenses remain relatively constant regardless of how much you produce or sell. These indirect costs are essential for keeping your business operational but don’t directly contribute to the creation of your products. The overhead rate has limitations when applying it to companies that have few overhead costs or when their costs are mostly tied to production.

Businesses incur various expenses to operate, and these are broadly categorized into direct and indirect costs. Direct costs are expenditures directly traceable to producing a specific product or service, such as raw materials or the wages of production line workers. In contrast, overhead costs, also known as indirect costs, are necessary expenses for the ongoing operation of a business but are not directly linked to creating a particular good or service. Manufacturing companies face substantial fixed costs for factory maintenance, machinery depreciation, and quality control. Unlike service-based firms, manufacturers must address production inefficiencies that can inflate overhead.